Bed joint reinforcement is an essential aspect of modern masonry construction, enhancing the structural performance and durability of masonry walls. By incorporating steel reinforcement into bed joints, builders can greatly reduce the risk of cracks, improve load-bearing capabilities, and enhance resistance to environmental factors. As the demand for resilient and sustainable construction continues to grow, understanding and effectively implementing bed joint reinforcement will remain a critical focus for architects, engineers, and builders alike. With proper execution, masonry structures can achieve both aesthetic appeal and long-lasting integrity, ensuring they stand the test of time.

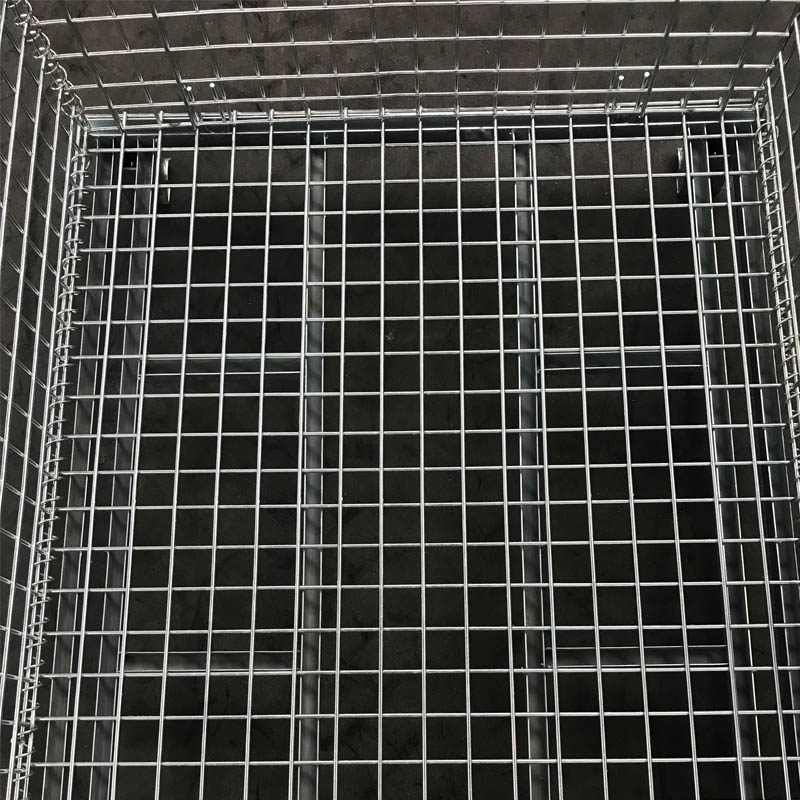

Welded wire is made from high-quality steel wires that are electrically welded at each intersection. This process creates a robust mesh that can withstand significant tension and pressure. Depending on the wire gauge, spacing, and finish, welded wire products can be tailored to suit various needs, whether for fencing, reinforcement in concrete structures, or as protective barriers for agricultural use.

Coil springs are an essential component in a multitude of mechanical systems, functioning as energy storage devices that help manage the forces exerted in various applications. Among these types, tiny coil springs, often referred to as micro springs or miniature coil springs, play a crucial role in a range of fields including electronics, automotive, medical devices, and consumer products. Their compact size and unique properties make them indispensable in many modern engineering solutions.

Chicken nets, also known as poultry nets or bird nets, are lightweight, flexible nets designed primarily for the containment and protection of poultry. These nets serve multiple purposes, including preventing chickens from straying, protecting them from predators, and minimizing disease spread. Made from durable materials, chicken nets are designed to withstand harsh weather conditions, ensuring that they provide long-lasting service in various farming environments.

Firstly, wall wire grid panels are celebrated for their durability and strength. Typically made from high-quality metal, they can support a variety of items, from lightweight decor to heavier products in retail environments. This strength allows users to maximize vertical space effectively, making it an excellent solution for small rooms or commercial spaces where floor space is limited. By using wall-mounted panels, individuals and businesses can display items attractively while keeping them easily accessible.

In conclusion, while wall tie prices may seem trivial in the grand scheme of construction and building maintenance, they carry substantial implications for structural integrity and overall project costs. Understanding the various factors that influence these prices — including material choice, installation labor, long-term durability, market fluctuations, and regulatory compliance — is crucial for anyone involved in the construction industry. By making informed decisions about wall ties, builders can ensure that they not only meet safety standards but also optimize their budgets and maintain the value of the structures they create.

Moreover, community engagement and responsible sourcing practices are essential components of sustainable iron plant operations. Many companies are adopting social responsibility frameworks that prioritize ethical labor practices, local community investments, and transparent supply chains. By sourcing raw materials responsibly and ensuring fair labor practices, iron plants can contribute positively to the communities in which they operate, building trust and support among stakeholders.

In conclusion, concrete formwork accessories play an indispensable role in the construction industry. From form ties and bracing to corner blocks and release agents, each accessory contributes to the overall effectiveness of the formwork system. By investing in quality accessories and understanding their function, construction professionals can enhance the durability and aesthetics of concrete structures, ensuring successful project outcomes. As technology advances, the development of innovative formwork accessories will continue to improve construction efficiency, safety, and quality. Emphasizing the importance of these components is essential for anyone involved in the concrete industry, as they form the backbone of any successful construction endeavor.

The term gauge refers to the thickness of the wire, with lower numbers indicating thicker wires. A wire gauge of 16 is approximately 1.29 millimeters in diameter, making it robust enough to hold its shape while still being pliable enough to work with hand tools. The versatility of 16 gauge wire comes from its ability to be bent, twisted, and shaped without breaking, which allows artists to explore their creativity.

Moreover, the Wire H Stakes is not just about individual glory. It often represents a community effort, with owners, trainers, and support staff coming together to achieve a common goal. Each participant plays a vital role in preparing the horse, from the meticulous training routines to the fine-tuning of nutrition and health care. The investment of time, effort, and resources reflects a deep commitment to the sport, making every aspect of the race feel like a culmination of collective aspirations.

In conclusion, wooden plant supports encapsulate the perfect blend of functionality, durability, and aesthetic appeal. They enhance the beauty of any garden, provide essential support for plants, and promote sustainable gardening practices. Whether you opt for commercially made supports or embark on a DIY journey, wooden plant supports are an excellent addition to any horticultural endeavor, ensuring your plants thrive while beautifying your outdoor space. With their myriad benefits, it’s no wonder they remain a popular choice among gardeners around the globe.

When selecting craft wire for a project, crafters should consider several factors, including the wire's gauge, material, and finish. Thicker gauges (lower numbers) provide strength and durability, while thinner gauges (higher numbers) offer flexibility and ease of manipulation. The choice of material often depends on the intended use; for example, jewelry makers might prefer softer wires like aluminum or copper, while builders might opt for stainless steel for its strength.

In conclusion, choosing the right field fence manufacturer is an investment in the future of any agricultural enterprise or property. By considering the quality of materials, the manufacturer’s reputation, customization options, aesthetic value, and customer service, landowners can make informed decisions that will not only enhance the functionality of their fencing but also support the overall longevity and success of their farming operations. Selecting a dependable manufacturer ensures that your field fence will stand the test of time, safeguarding both your livestock and your investment.

Aesthetics play a crucial role in choosing fencing materials, especially for residential properties. PVC coated wire mesh fencing comes in a variety of colors and finishes, allowing property owners to select a design that complements their landscape. Whether you prefer a vibrant green that blends with the garden or a neutral black that adds elegance, the PVC coating offers both functionality and visual appeal. This versatility makes it a popular choice for parks, schools, residential areas, and commercial properties alike.

In conclusion, 2-inch extension springs play a crucial role in various applications across multiple industries. Their unique design characteristics, coupled with their versatility and benefits, make them indispensable components in modern mechanical systems. Understanding the significance of these springs not only allows manufacturers to optimize their products but also helps consumers appreciate the intricate mechanisms behind everyday objects. As technology continues to advance, the role of extension springs, including the trusty 2-inch variety, will undoubtedly remain vital in the world of engineering and design.

Craft wire is typically made from different metals, with aluminum, copper, stainless steel, and nickel being the most common. Each type has its own unique properties. For instance, aluminum wire is lightweight and resistant to rust, making it a favorite for outdoor decorations. Copper wire is favored for its malleability and ability to hold intricate shapes, while stainless steel offers durability and a polished finish for more sophisticated projects.